Since our last post, Texas 1’s state-of-the-art mechanical plant has begun to take shape. The chilled water system design allows for maximum cooling flexibility from standard single cabinet deployments to high density configurations. Even the most complex High Performance Computing (HPC) environments can be properly cooled in Texas 1.

Beginning with two diverse water feeds, cooling at Texas 1 is designed to be inherently resilient:

Flowing through six cooling towers, these reinforced concrete walls form a reservoir for 130,000 gallons of water.

From the cooling towers outside, water flows into multiple 550-ton green chillers.

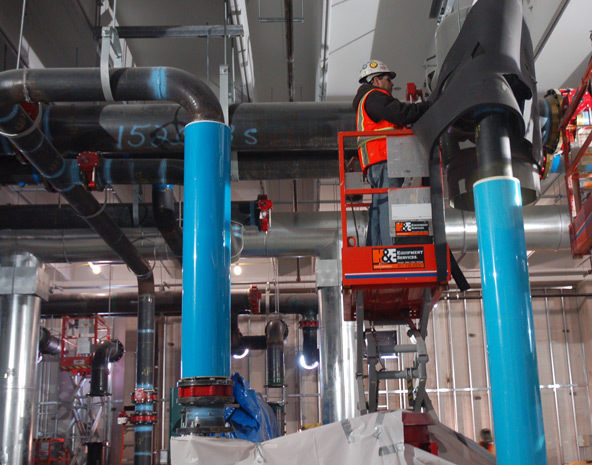

Chilled water is then pumped through overhead piping into the rest of the facility.

Color coded for easy identification, chilled water flows into the system’s ring architecture through the light blue pipe and returns through the darker blue pipes.

Texas 1 is outfitted with top-of-the-line Armstrong chilled water pumps.

Encircling the gallery, 12” insulated chilled water pipes lay five feet below the raised floor. Passing through multiple 50-ton CRAHs, cooled air will blow over the trench, under the raised floor and directed to where customers need it.